METAPOR® Block Material

For various applications, different METAPOR® products are available.

The major differences are within the granule type, air permeability, pore size and temperature stability.

| Product | HD 100 AL | HD 210 AL | BF 100 AL | BF 210 AL | MC 100 AL | MC 200 AL | MC 240 AL |

|---|---|---|---|---|---|---|---|

| Air permeability * | 50% | 50% | 100% | 100% | 800% | 700% | 800% |

| Application | |||||||

| Vacuum clamping | |||||||

| Air cushion / air film | |||||||

| Injection mould and blow mould venting | – | – | – | – | – | – | – |

| Ceramic industry | – | – | – | – | – | – | |

| EPS, EPE, EPP foam moulds (resist high pressure steam) | – | – | – | – | – | – | |

| Thermoforming | |||||||

| PET | – | – | – | ||||

| PP | – | – | – | ||||

| PS | – | – | – | ||||

| PE | – | – | – | ||||

| PVC | – | – | – | ||||

| ABS | – | – | – | ||||

| PC | – | – | – | – | – | ||

| Transparent applications | – | – | – | ||||

| High temperature | |||||||

| Low surface roughness | |||||||

| High surface resistance | |||||||

| Porosity | 20% | 21% | 17% | 19% | 26% | 22% | 26% |

| Heat resistance | 108 °C | 240 °C | 108 °C | 240 °C | 108 °C | 200 °C | 240 °C |

| Available in 500 x 500 mm | |||||||

| Available in 1000 x 500 mm | |||||||

| Compare | Compare | Compare | Compare | Compare | Compare | Compare |

* Reference values to the air permeability of METAPOR® BF 100 AL

| Product | MC 100 WHITE | CE 100 WHITE | CE 170 WHITE |

|---|---|---|---|

| Air permeability * | 800% | 100% | 100% |

| Application | |||

| Vacuum clamping | |||

| Air cushion / air film | |||

| Injection mould and blow mould venting | – | – | – |

| Ceramic industry | |||

| EPS, EPE, EPP foam moulds (resist high pressure steam) | – | – | – |

| Thermoforming | |||

| PET | – | – | – |

| PP | – | – | – |

| PS | – | – | – |

| PE | – | – | – |

| PVC | – | – | – |

| ABS | – | – | – |

| PC | – | – | – |

| Transparent applications | – | – | – |

| High temperature | |||

| Low surface roughness | |||

| High surface resistance | |||

| Porosity | 20% | 20% | 19% |

| Heat resistance | 108 °C | 108 °C | 170 °C |

| Available in 500 x 500 mm | |||

| Available in 1000 x 500 mm | |||

| Compare | Compare | Compare |

* Reference values to the air permeability of METAPOR® BF 100 AL

| Product | MA 100 BLACK | ES 240 INOX |

|---|---|---|

| Air permeability * | 100% | 200% |

| Application | ||

| Vacuum clamping | ||

| Air cushion / air film | – | – |

| Injection mould and blow mould venting | – | |

| Ceramic industry | – | – |

| EPS, EPE, EPP foam moulds (resist high pressure steam) | – | – |

| Thermoforming | ||

| PET | – | – |

| PP | – | – |

| PS | – | – |

| PE | – | – |

| PVC | – | – |

| ABS | – | – |

| PC | – | – |

| Transparent applications | – | – |

| High temperature | ||

| Low surface roughness | ||

| High surface resistance | ||

| Porosity | 21% | 29% |

| Heat resistance | 108 °C | 240 °C |

| Available in 500 x 500 mm | ||

| Available in 1000 x 500 mm | ||

| Compare | Compare |

* Reference values to the air permeability of METAPOR® BF 100 AL

| Product |

|---|

| Air permeability * |

| Application |

| Vacuum clamping |

| Air cushion / air film |

| Injection mould and blow mould venting |

| Ceramic industry |

| EPS, EPE, EPP foam moulds (resist high pressure steam) |

| Thermoforming |

| PET |

| PP |

| PS |

| PE |

| PVC |

| ABS |

| PC |

| Transparent applications |

| High temperature |

| Low surface roughness |

| High surface resistance |

| Porosity |

| Heat resistance |

| Available in 500 x 500 mm |

| Available in 1000 x 500 mm |

* Reference values to the air permeability of METAPOR® BF 100 AL

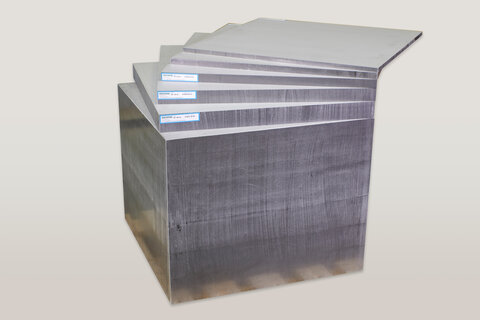

Availability

All METAPOR® products are available in square slabs of 500 x 500 mm with a thickness range from 10 mm up to 420 mm.

METAPOR® HD 100 AL / HD 210 AL and BF 100 AL are also available in slabs of 1000 x 500 mm with a thickness range from 15 mm up to 200 mm.

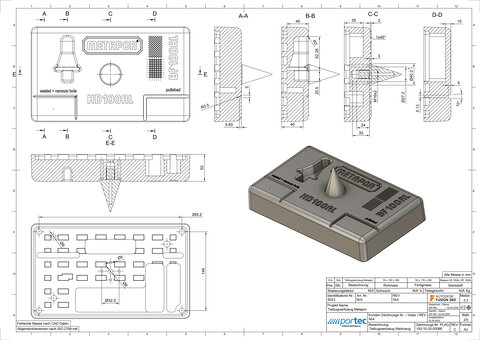

Services

Component and Assembly Service

It’s possible to get your final METAPOR® product from us and our Partners. If you wish to get finished parts made out of METAPOR® please send us your inquiry. We are able to produce and assemble your parts based on technical drawings or 3D data.

Many of our METAPOR® distributors are specialized in certain fields of applications. We are looking forward to connect you with your nearest and best fitting METAPOR® partner.

All out of one hand makes your sourcing less complicated, efficient and saves time and money.

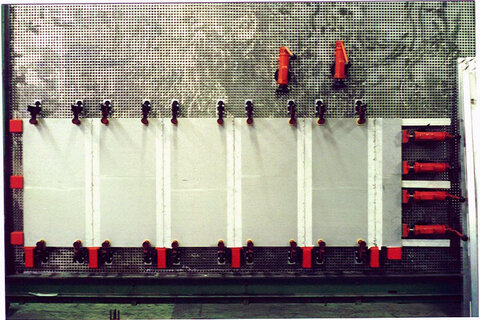

Machining

The machinability of METAPOR® is excellent. It’s possible to machine METAPOR® faster than aluminium and due to its naturally porosity there’s no need to drill vacuum holes in it.

METAPOR® has to be machined dry, without any coolant liquid. To prevent clogging of the pores, very sharp tools made out of HSS or carbide with edge angles for aluminium is recommended to use. It’s possible to saw, mill, turn, grind and even polish METAPOR® without closing the pores.

Best results in milling 3D geometries have been achieved with following parameters:

| Cutter Type: | SANDVIK, Ø 6 mm ball nose, uncoated R216.42-06030-AK10A H10F |

| Speed rpm: | 7750 min -1 |

| Step over: | 0.05 mm |

| Feed per tooth: | 0.05 mm |

| Coolant: | Compressed air or dry |

Best milling results for face milling have been achieved with the following parameters:

| Cutter Type: | Corner cutter head Ø 160mm; 7 cutting edges; Indexable inserts 90° APHT |

| Speed rpm: | 500 min-1 |

| Feed per tooth: | max. 0.142 mm |

| Coolant: | Compressed air or dry |

METAPOR® is a registered trademark of Portec in Switzerland.