ESPOR® Casting Moulds

ESPOR® air-permeable casting technology is a patented combination of materials and process developed by Portec.

ESPOR® technology is used to manufacture micro-porous, air-permeable products for numerous industrial applications where even air-permeability is required.

Material

ESPOR® products are made from a composite material of aluminium granules and epoxy resin. Different sizes of aluminium granules are available, thus enabling production of products with varied levels of air-permeability. For faster cycle times it is also possible to incorporate metal cooling lines within the ESPOR® products.

Applications, Availability and Services

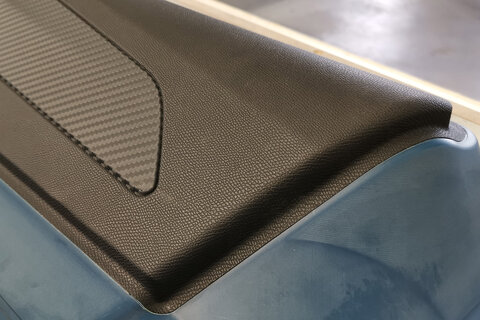

The most common application of ESPOR® technology is to manufacture air-permeable moulds for vacuum forming and thermoforming processes for various interior components in automobiles, in the packaging industry and many other market-segments.

ESPOR® is especially useful for duplication of complex textures such as leather grain and other intricate patterns (Production of IMG-Moulds).

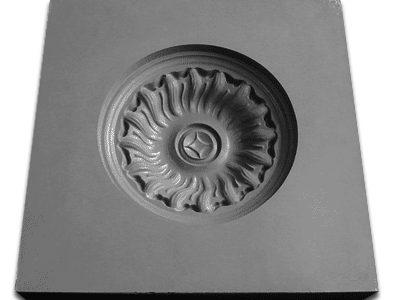

ESPOR® is used for creation of difficult to machine shapes, making cast multiples, ornaments with fine details as well as production of large and deep objects.

ESPOR® is also used to produce vacuum holding fixtures and air cushion systems for material handling applications.

Machining

ESPOR® moulds are ready to use. No machining is needed anymore.

Process and Pattern Requirements

- ESPOR® technology requires a physical pattern in order to cast a reverse impression.

- The pattern for ESPOR® casting technology must be completely rigid.

- Materials such as wood, epoxy and metals are acceptable. Solid patterns produced by various Rapid Prototyping machines can also be used.

- Flexible materials such as silicones cannot be used, and thin wall rigid materials may need to be reinforced in order to sustain the forces of the process.

- The pattern must have a minimum draft angle of 2° in order to facilitate de-moulding.

- The process cannot tolerate even minor undercuts in the pattern. In cases where a textured surface is applied onto a pattern, a low-strength adhesive must be used to ensure that the texture can be separated from the pattern during de-moulding.

- ESPOR® materials do not exhibit a detectable shrinkage, so the pattern does not require any scaling.

ESPOR® is a registered trademark of Portec in Switzerland.