METAPOR®: Porous material for Vacuum Clamping Applications

METAPOR® offers new possibilities as a result of its easy machining properties.

A constant decompression within the material allows a strong holding force, even when the clamping surface is “only” partially covered.

With clamping elements made out of METAPOR®, Work pieces can be precisely and evenly fixed without deformations.

Your high requirements placed on surface smoothness and flatness are able to be met without any problems with METAPOR®.

Due to the absence of any grooves and drill holes, even sensitive parts will not show any deformation.

Statical adhesion can be eliminated by using compressed air, which creates a smooth and even air cushion.

Advantages

- Even vacuum and homogeneous airflow on the entire surface.

- Deformation-free fixing due to micro-porous surface (high flatness and parallelism)

- Very thin and sensitive films and parts will be clamped without damage (this can happen when drilled aluminium plates are used)

- Areas that should not have air permeability can be easily covered.

- Economical construction; no drill-holes needed whatsoever.

METAPOR® Products for Vacuum Clamping Applications

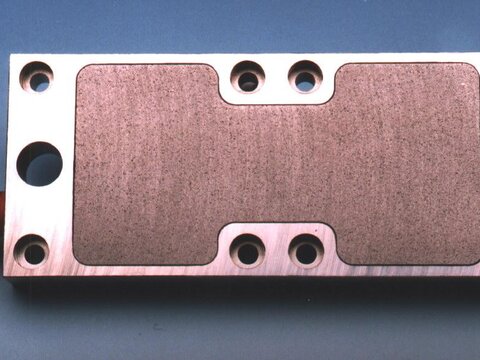

METAPOR® BF100 AL is advantageous for vacuum clamping devices for fixation of sensitive materials like very thin films (around 0,01 mm) or for engraving flat objects. It allows steady clamping forces even with partial covering of the surface.

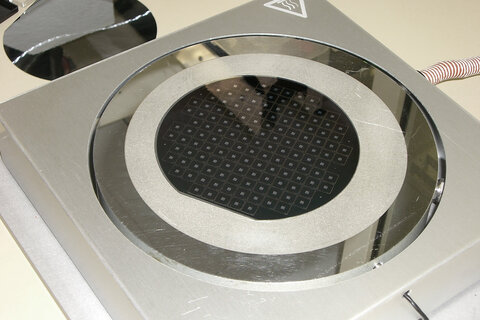

METAPOR® CE 100 White is an extremely fine porous material with a white surface. It has proven to be very useful in silicon-wafer production, also due to its strong surface hardness and precision milling capability. Flatness of vacuum chuck surfaces less than 5 microns. Clean room surrounding approved. It allows steady clamping forces even with partial covering of the surface.

Vacuum clamping devices made out of METAPOR® MC 100 AL are used for complex 3D-shapes and for complete surface coverage, to clamp parts and films without any deformation.

METAPOR® MA100 BLACK is a unique micro porous product for applications where a complete dark surface is needed and no reflections are allowed. This porous material will stay Black even after milling. It can be used e.g. as a vacuum chuck for 3D- and Optical-measurement equipment or e.g. to make quality inspections for transparent RFID foils. Like our other products is it possible to precisely clamp pieces with very high flatness requirements and without deformations. It allows steady clamping forces even with partial covering of the surface.

Applications

- Plane clamping: worktables, fixing foils, printing tables, measuring tables, engraving tables, clamping inserts within compression moulds.

- Profile clamping: vacuum supported form grippers for complex tools, trimming of thermoformed parts. Ultrasonic-cutting of slush-skins e.g. for instrument panels in the automotive industry

Semiconductor Industry

Clamping devices for the Semiconductor industry made out of porous material (METAPOR® Nonmetal types) offer the advantage that they can be easily machined, having a smooth surface (less friction), even air distribution and a reasonable price.

The material is ideal because it is more or less self-cleaning and therefore very durable. During the use with cleaned, compressed air this porous material is even suitable for clean room conditions.

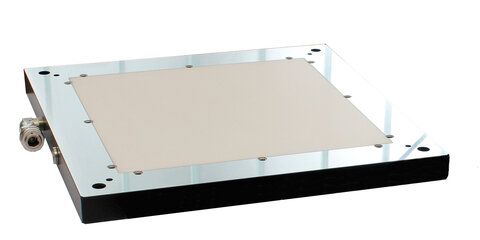

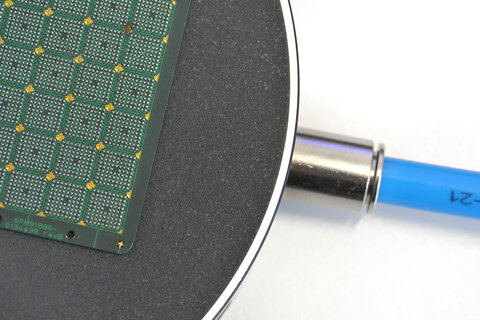

METAPOR® CE 100 WHITE chucks are widely used in the microelecronic industry for wafer processing, IC assembly, chip- and wire bonding.

A micro-porous ceramic working disk produced out of a METAPOR® CE 100 WHITE slab is a special tool for clamping and bearing in various semiconductor wafer production processes, and is applied to processes such as thinning, dicing, grinding, cleaning and handling.

METAPOR® CE 100 WHITE can be used for new and refurbished porous ceramic chucks for various semiconductor machine producers.

Quality control

Clamping devices for the quality assurance industry made out of METAPOR® assure a very precise and accurate clamping of your test parts. It’s possible to use our Material for optical Quality checks and measuring- inspections. Our components are compatible for various measuring machines.

Plant manufacturers use METAPOR® within their process chain to clamp and transport their components reliable and repeatable.

Recommended METAPOR® Products for vacuum clamping

| Product | Application Characteristics | Density (g/cm3) | Flexural strength (N/mm2) | Air flow rates * |

|---|---|---|---|---|

| BF 100 AL | Plane clamping Very sensitive parts and thin films Partial coverage of clamping surface possible | 1.8 | 52 | 1.4 |

| CE 100 WHITE | Plane clamping High surface resistant Very sensitive parts and thin films – semiconductor industry Partial coverage of clamping surface possible | 1.7 | 28 | 1.4 |

| MC 100 AL | Plane and profile clamping Full coverage of clamping surface required Maximum airflow | 1.7 | 40 | 11.5 |

| MA 100 BLACK | Plane and profile clamping Partial coverage of clamping surface possible Complete Black porous material | 3.3 | 32 | 1.5 |

* Air flow rates at pressure difference of 1 bar/10mm METAPOR slab (per cm2 per minute in litres)

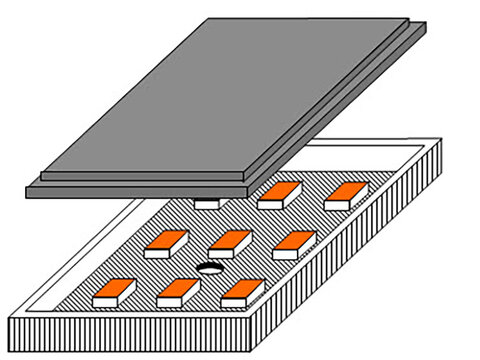

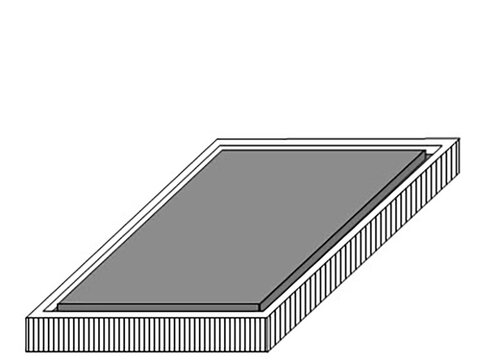

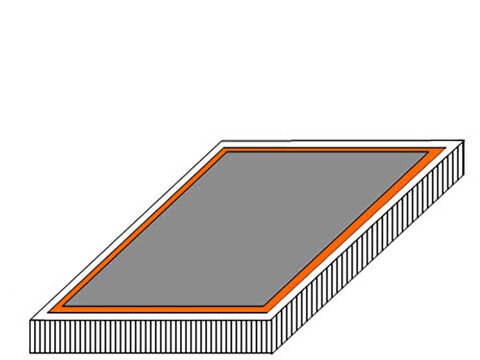

Principle of a METAPOR® vacuum clamping device

Before gluing the METAPOR® slab, degrease the surfaces of the support elements and coat them with e.g. ARALDIT 2014 adhesive. Afterwards, fill in the slab joint of the METAPOR® slab, approx. 2 mm, with ARALDIT 2014 or silicone.

| METAPOR®-slab: | 10 - 15 mm thickness, milled on first side. |

| Base plate / Support frame: | Aluminium plate, milled support elements |

| Dimensions of support elements: | Approx. 20 mm x 10 mm x 5 mm (LxWxH) |

| Distance of support elements: | Approx. 40 mm (center – center) |